Adapters

Barbs

A barb is used to connect flexible tubing to any number of other components. Barbs are cylindrical pieces with a series of ridges that work by gripping the interior wall of a tube after a simple push-connection. Once inserted and secured, they are not easily disconnected. Due to their simple push-connection design, barbed fittings are typically used in low pressure applications (around 200psi or lower). The advantages of barbs are their simplicity, low cost, variety of materials, and ease of installation.

Clamps

In a tubing assembly, clamps are typically used like a valve. They can provide partial or complete fluid flow stoppage without puncturing or otherwise damaging the tubing. Clamps are installed over the outside of a tube, which allows them to be added to a system, even after the assembly has been completed.

Coned Fittings

A coned fitting is a threaded component that can make a tubing connection into a coned port, and can be made from a variety of materials to suit the application. Coned fittings are often selected for high-pressure applications.

Coupling

Ferrules

A ferrule normally refers to a circular clamp used for fastening, sealing, or reinforcement. They are typically made from metal or plastic, and also go by the names “grommet” or “compression fitting.” An everyday example would be the metal clamp on the end of a pencil that holds the eraser in place. Ferrules can be used in a tubing assembly to join two components together with a water-tight seal, or to strengthen and provide support for a critical/high pressure section of tubing.

Flat-Bottom Fittings

These threaded fittings make an easy and repeatable connection with a variety of standard and custom port sizes. They can also be referred to as “flanged fittings.” The advantage of flat-bottom fittings is their compatibility with precision thermo-molded FormFit flanges from CMG. Together, they can create a chemically-inert, leak-free seal that is easily installed and serviced.

Labels (Markers)

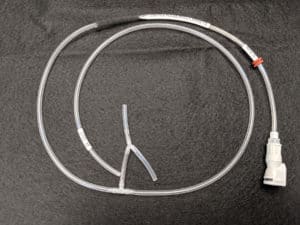

Luers

A luer taper or luer lock style connector is used for making leak-free connections in many medical and laboratory applications. In a luer lock connector, the female portion of the fitting typically has a flange that screws into the tapered threads of the male fitting. This allows a secure connection that is easily exchanged or replaced.

Nuts

A nut is a very common type of fastener that comes in many shapes and sizes, but always consists of a threaded hole that typically mates with a bolt. The nut and bolt threads will match, which allows the friction between them to fasten multiple parts together. To prevent a nut from becoming loose, they are often paired with a locking device such as a lock washer, lock nut, or jam nut.

O-Rings

The purpose of an O-ring is to aid in creating a tight seal. In a typical tubing assembly from CMG, the O-ring will fit securely between the tubing flange and a washer. A threaded or other type of connection fitting will screw in to a port to provide pressure against the washer, which then compresses the O-ring. The compressed O-ring provides a leak-free, chemically inert, high pressure seal when paired with our FormFit thermo-molded flanges.

Quick-Disconnect

Quick-disconnect fittings are exactly what they sound like. They allow the user to quickly and easily make and break tubing connections while the fittings stay attached to the tubing. The advantages are ease of service and installation, and allowing many re-connections without degrading the quality of the connection.

Valves

Valves are used to regulate or stop the flow of liquids and gases. They can serve multiple purposes in an application, and are therefore categorized by their use. Isolation valves can be used to cut off flow to/from part of a system. This could allow maintenance, installation, or emergency shut-off. Check valves or “non-return valves” allow a fluid to flow freely in only one direction, preventing flow in the opposite direction. A throttling valve allows control over the quantity or pressure of a fluid that is flowing through an application.

Washers

Typically a washer is used to distribute the load of a fastener (like a threaded connection fitting) onto another piece of hardware when torque is applied. A plain washer or “flat washer” is essentially just a small disc that typically has an OD (outer diameter) about twice the size of its ID (inner diameter). There are many types of washers, but flat washers are the most commonly used in a flanged tubing assembly from CMG. They distribute the pressure from a fitting onto the O-ring, spreading the load evenly to help create the leak-free seal.