Benefits of Plastics Machining at CMG

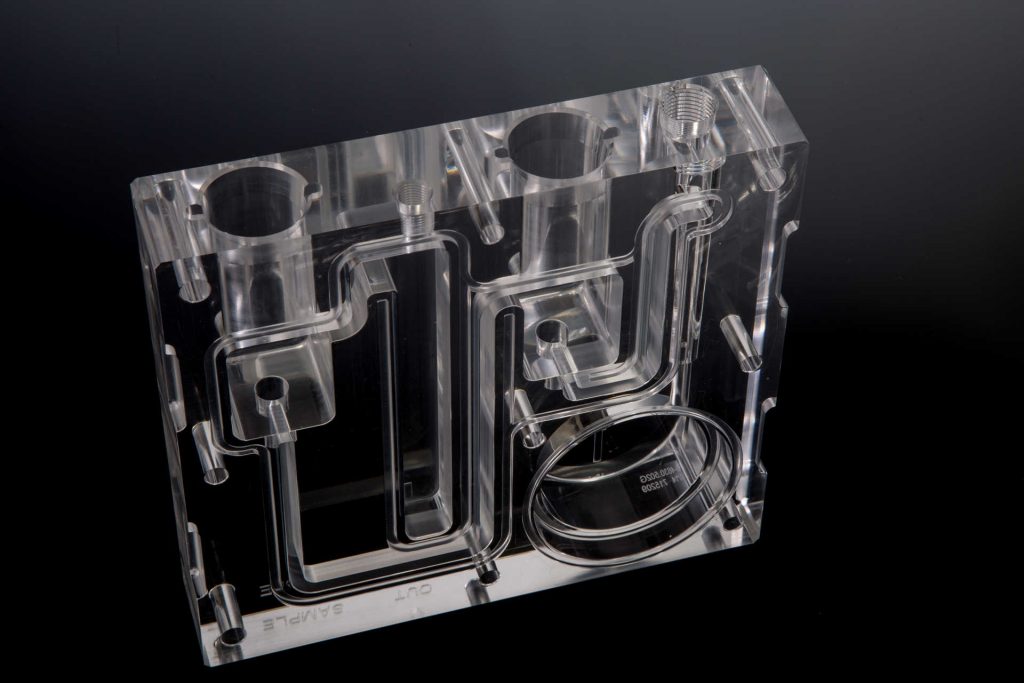

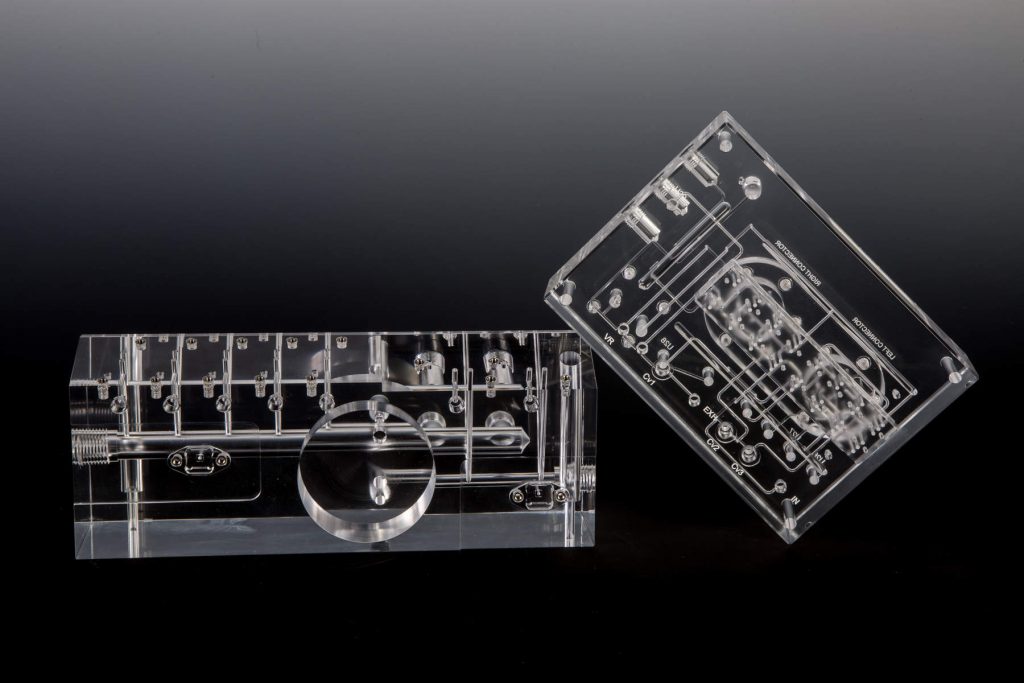

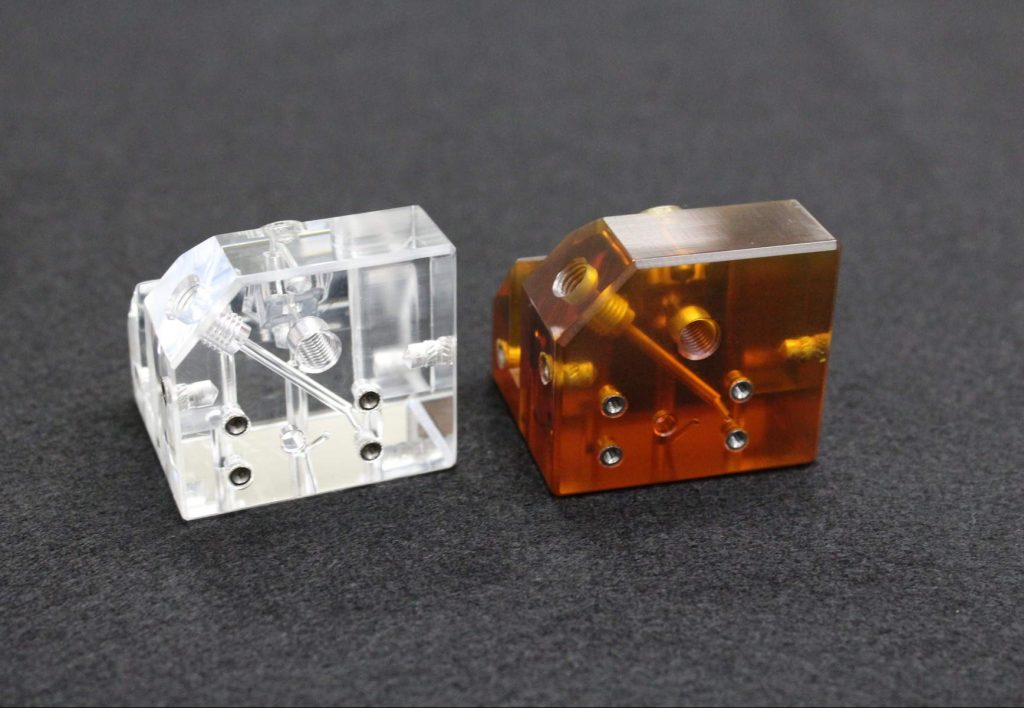

Piedmont CMG’s expertise in performance plastics and fluidics, combined with decades of precision machining for life science and aerospace applications, along with our cutting-edge, proprietary software and processes, have put us in a unique position in our industry. We commonly manufacture the most critical plastic and fluidic components of new devices, requiring precision, reliability, traceability, accountability, and a close partnership with our valued customers.

Experienced Supplier & Vendor of CNC Machined Plastics

CMG is a critical supplier and reliable vendor of quality CNC machined plastic parts and components. The diversity of talent and experience in our organization is unrivaled in the industry. We continually update and improve our equipment, tools, techniques, training, and procedures to stay on the cutting-edge (pun intended) of plastics machining technology.

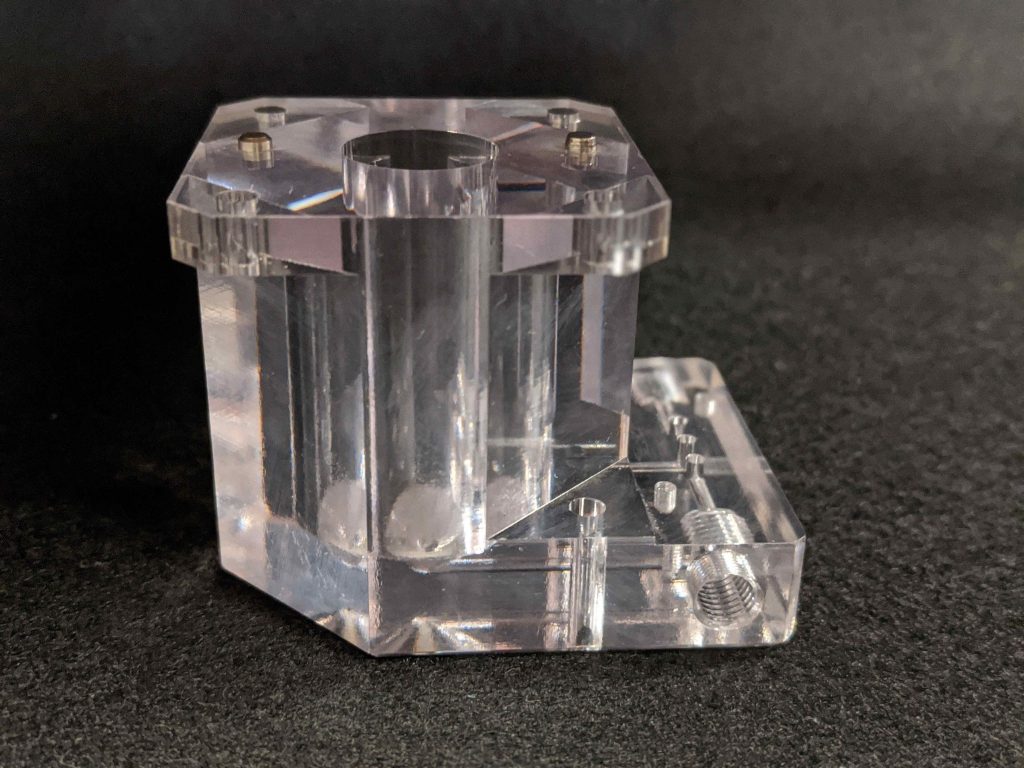

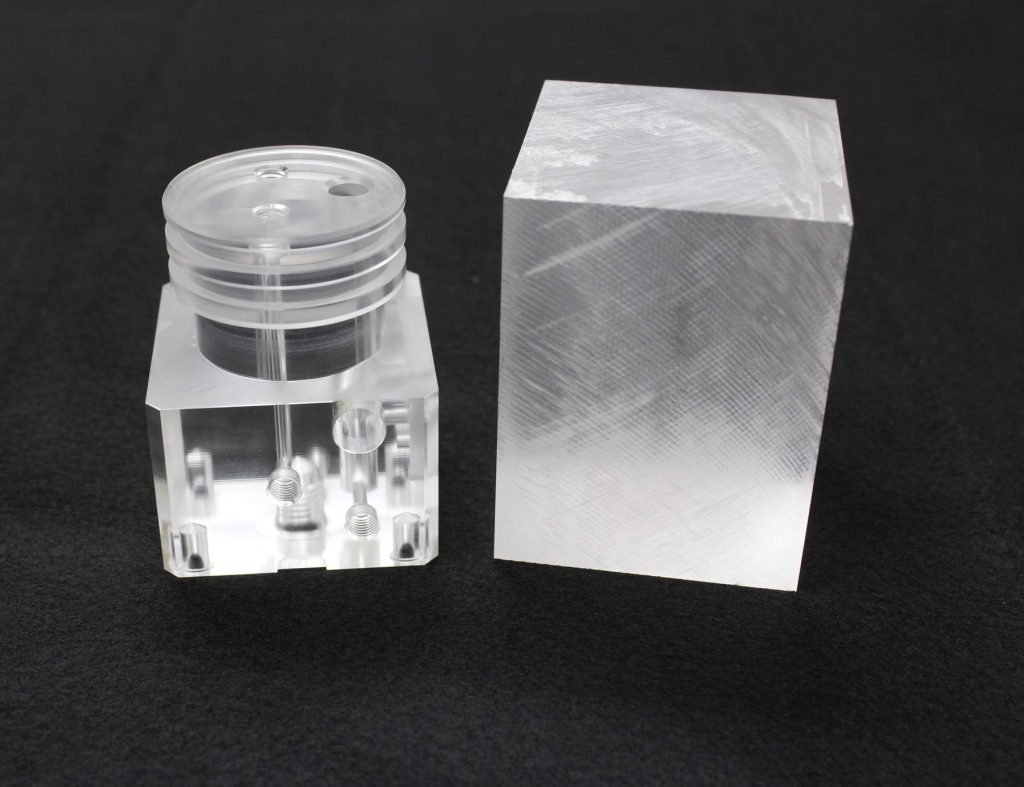

CNC Precision Machined Performance Plastics

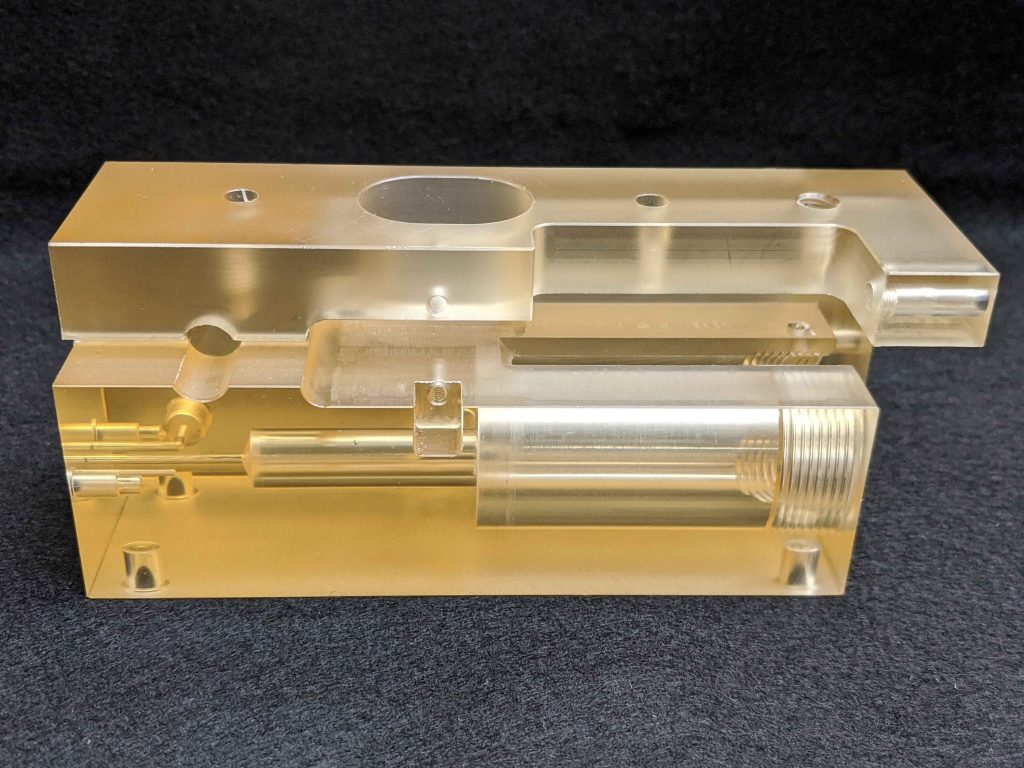

At Piedmont CMG, we’ve been machining high performance plastics, engineering thermoplastics, and a wide variety of standard polymers for decades. OEMs turn to us for our depth and breadth of experience with all types of plastics for the most critical components and fluidic hubs that are essential to the success of their applications. The latest high-speed CNC milling equipment and techniques are just standard operating procedure in our machining facility.

What is CNC Machining for Plastics?

CNC (computer numerical control) machining for plastics is the use of computer programs and electronic integration of automated control for advanced machining techniques and procedures to meet tight tolerances and custom specifications on critical plastic parts and components.

Coded programs and visual work instructions aid CNC machine operators in producing contract manufactured plastic parts that are designed to customer requirements.

Why Choose CNC Machined Plastics?

CNC machined plastics provide many benefits over traditional, non-computerized machining with manual controls. A CNC machine provides motorized, maneuverable platforms and tools, which are controlled by a computer program and transferred to the CNC machine through computer code.

The code programs are generated through CAD and CAM software, and are optimized by an experienced machinist and programmer to provide specific instructions to the equipment. This aids the CNC machines and operators in producing intricate parts with a variety of tools in the most efficient manner, aligning with the goals of lean manufacturing.

What is the Difference in CNC Turning and Milling?

In plastics machining, the major difference between CNC turning and milling is the primary moving piece during the manufacturing process. In CNC turning, the plastic material is rotated at a high rate of speed while cutting tools remove material to achieve the desired shape or feature. In CNC milling, the plastic material is held in place by a vice or fixture, while the cutting tools rotate and move around it to machine the desired features.

Common Types & Uses of CNC Machined Plastic

CNC machined plastic parts are used for a wide variety of purposes in many markets and industries all over the world. Some common uses of machined plastic parts that we have produced over the years include:

- Manifolds

- Pump heads

- Gears

- Drains

- Sprockets

- Mandrills

- Bushings

- Bearings

- Star Wheels

- Insulators

Best Plastics for CNC Machining

Why are these materials a good fit for CNC machining? These materials hold tolerances well, and they are conducive to faster and quicker machining techniques without creating difficult-to-remove burrs. These materials can also be held by vacuum or vice fixtures without causing deformity to the part being manufactured.

What Machining Operations are Used in

Plastics CNC Machining?

- Boring

- Drilling

- Grooving

- Knurling

- Milling

- Reaming

- Tapping

- Threading

- Turning