Multilayered Diffusion Bonded Plastic Manifolds

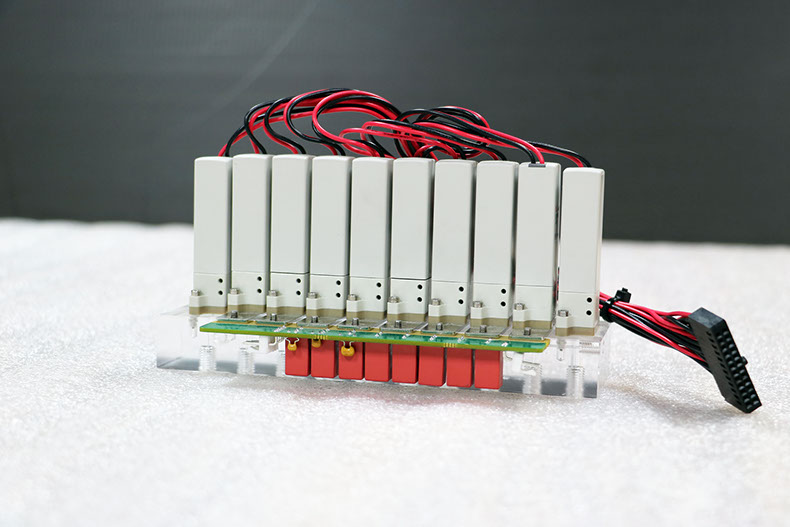

Piedmont CMG supports the medical analytical industry with precision machining, optically clear diffusion bonded and machined manifolds, and value added assemblies. Our customers are OEMs seeking strategic suppliers that provide reliability, consistency, competitiveness, and personal service, which provides us with a competitive advantage. Please contact Piedmont CMG for an in-depth review or tour of our facilities.

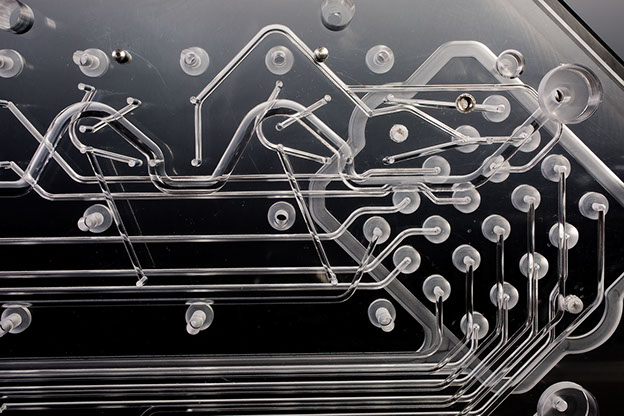

What is Diffusion Bonding?

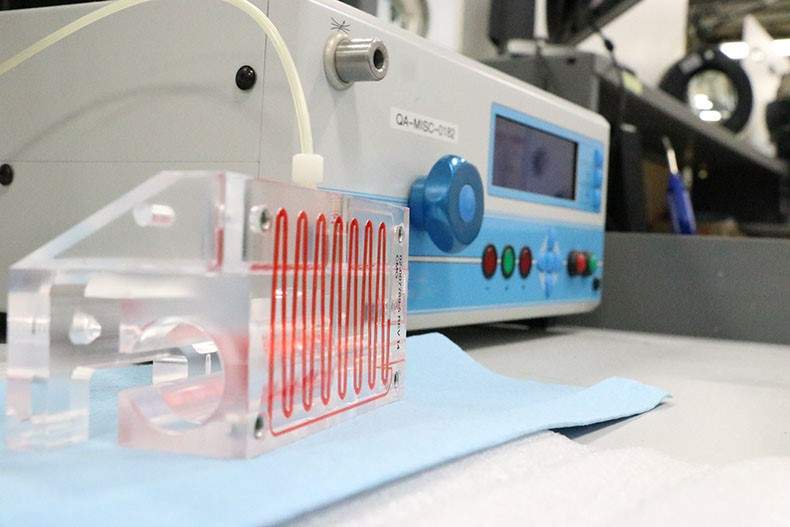

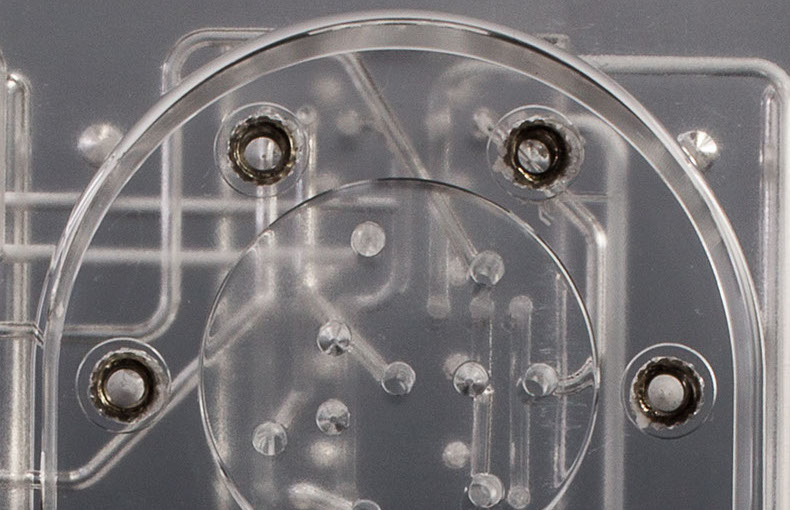

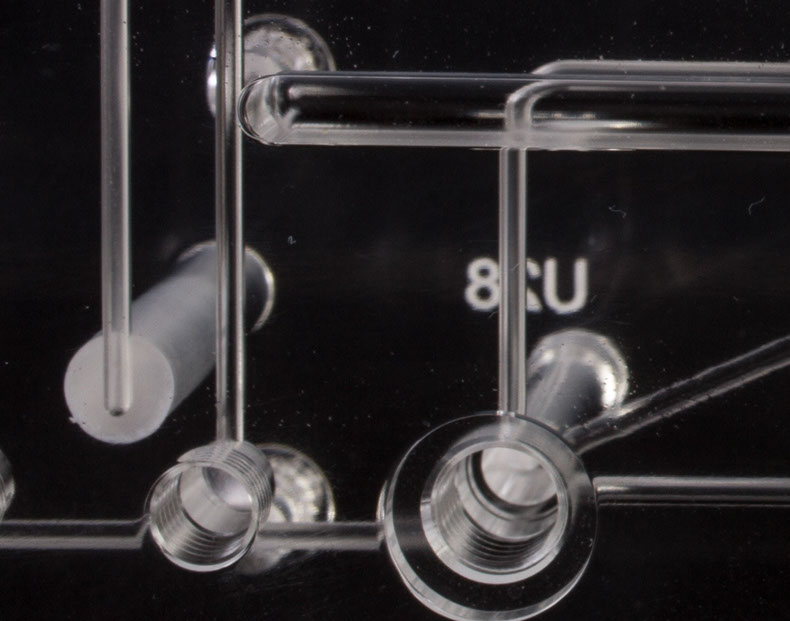

Multiple layers of plastic are molecularly fused to create a 3 dimensional microfluidic circuit. In concept, similar to an electronic circuit board, diffusion bonded manifolds concentrate fluid paths into a limited space requirement.

Advantages

- Optically Clear

- Complex Features

- Precise Tolerances

- Ease of Assembly

- Lower Maintenance

- Visible Flow Paths

- Volume Reduction

- Burr free intersections

Common Materials

- Acrylic (PMMA)

- Ultem (Polyetherimide)

- Polycarbonate (PC)

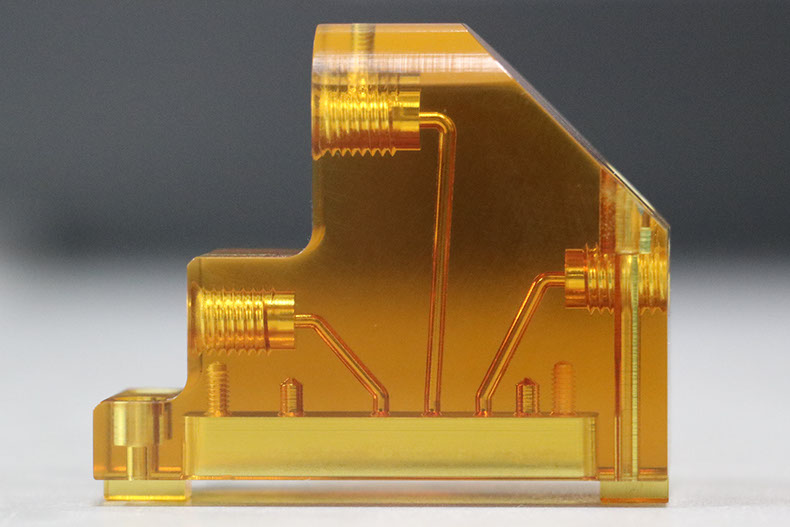

Diffusion Bonded Ultem Manifolds

Diffusion bonded Ultem (Polyetherimide or PEI) manifolds provide the flexibility of design that makes fluidic manifolds so appealing. Bonded Ultem (Polyetherimide) also provides excellent thermal, chemical, and physical properties that allow it to be used in the most demanding, harsh environments and applications.

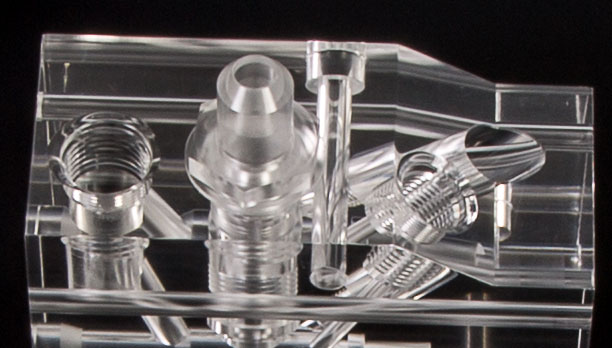

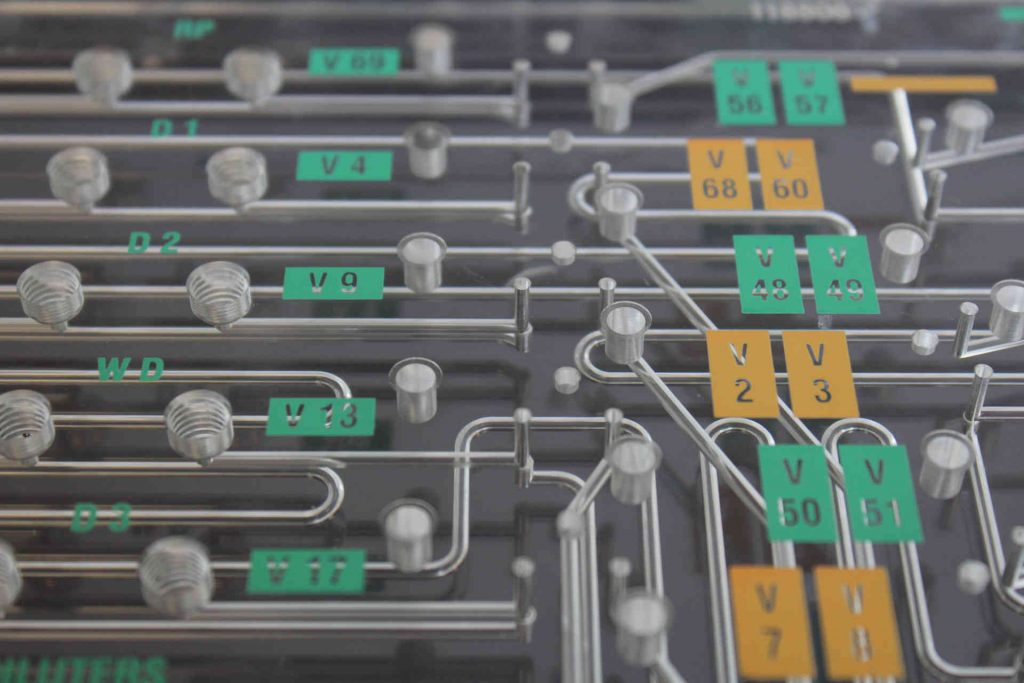

Machined Plastic Manifolds

This cost effective solution integrates a fluidic flow path with straight machined features. The absence of bonding allows for the use of a large variety of engineered plastic materials.

Common Materials

- PEEK

- HDPE

- Polycarbonate

- Acrylic

- PVC

- Polysulfone

- Noryl

- Ertalyte

- Teflon

- ABS

- Isoplast

- PVDF