POLYPROPYLENE Key Facts

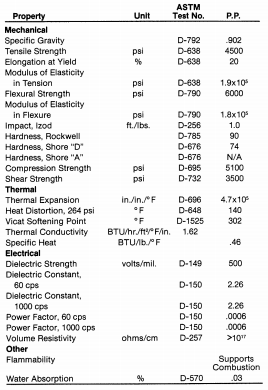

Polypropylene offers a good balance of overall physical properties. These properties include chemical, moisture and heat resistance. Polypropylene resists chemical attack and staining through expo sure to aqueous solutions of inorganic salts, mineral acids, and bases.

Polypropylene provides remarkable performance, compared to most thermoplastic products, in applications never before possible with thermoplastics.

Key Benefits of POLYPROPYLENE

Light Weight-Its unusually low specific gravity of 0.89 to 0.91 makes it the lightest of all commercially available thermoplastics.

Heat Resistance– The ability to withstand constant temperatures of 280°F without deformation or detect able change in mechanical properties makes it an ideal material for products that must be subjected to sterilization temperatures of 248° F and over.

Abrasion Resistance– Surface hardness of commercial polypropylene is excellent, due in large measure to its crystalline structure. The abrasion resistance of this material is superior to that of all low cost thermoplastics.

Chemical Resistance– It has excellent resistance to a greater variety of chemical reagents at temperatures higher than those tolerated by other thermoplastics. It is unaffected by aqueous solutions of inorganic salts and by practically all mineral acids and bases, even when highly concentrated at temperatures over 140° F. It resists 80%sulphuric acid and concentrated hydrochloric acid up to 212° F. In the presence of strong oxidizing chemicals, suitable anti-oxidants should be added to the polypropylene. It is practically immune to stress cracking when exposed to alcohols, soap solutions, synthetic detergents, acetic acid.

Gas Barrier-It has excellent resistance to gas and water vapor.

Formability and Fabrication-The same techniques used in forming and fabricating linear polyethylene are used here.

Machinability– Easily machined at relatively high speeds, on conventional machine tools. Polypropylene can also be fabricated on standard woodworking equipment such as molders, dowelers and planers.

Bonding-Because of its outstanding resistance to chemicals, polypropylene does not lend itself to sol vent bonding or cementing. However, joints of great strength can be obtained by hot nitrogen welding, spin welding, and hot plate fusion.

Applications of POLYPROPYLENE

• Chemical . . . tanks, scrubbers and ducts

• Electronic . . . radio and TV equipment

• Electrical . . . home appliances

• Automotive . . . battery cases, under-hood covers and shrouds, and non-structural uses such as fender extenders

• Electroplating . . . plating barrels

• Photo and film industry . . . sinks and developing trays