NYLON 101 Key Facts

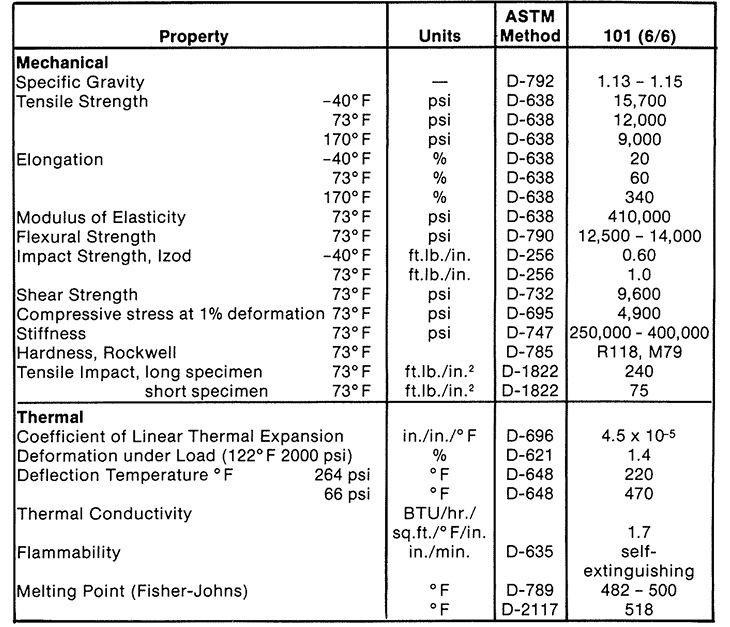

Nylon 101, a type 6/6 nylon, was the first nylon material available in rod, sheet and tube form for industrial use and, since its introduction in 1946, has become the most widely used nylon in American industry. Its broad acceptance in such diverse industries as food processing (FDA approved), machinery and electronics has come about because of the premium properties it offers. Nylon 101 is the strongest, stiffest, and has the highest melting point of any unmodified nylon processed by conventional extrusion techniques, and replaces a wide range of conventional materials-including steel, bronze, brass, aluminum, laminated phenolic, wood and rubber. It can replace such vastly different materials as steel and rubber because its properties – low friction, high strength, toughness and good abrasion resistance- lie between those of rubber and steel. It is this combination of properties, rather than a single area of superiority, which make nylon 101 so useful for many different applications.

Key Benefits of NYLON 101

- High wear and abrasion resistance

- Low coefficient of friction

- Resiliency and impact resistance

- Non-abrasive to other materials

- Noise dampening characteristics

- Good electrical insulating properties

- Resistance to alkalies and organic chemicals

- Able to operate with or without lubrication

- FDA approved

- Lightweight

- Conformability

Applications of NYLON 101

- Bearings

- Rollers

- Fasteners

- Bushings

- Guides

- Sleeves

- Valve seats

- Gears

- Liners

- Thrust washers

- Insulators

- Tooling fixtures

- Seals

- Cams and cam followers

- Forming dies

- Wear surfaces