KYDEX® Key Facts

Kydex is offered in 3 different formulations for aircraft interior applications. They are available from authorized Kydex sheet distributors. Customer sheet sized are also available to minimize trim scrap.

Kydex® 100 – The original, most widely known formulation of Kydex, field proven for over 25 years. Standard gauges are available from .28” to .250”. In all gauges, it meets FAR §25.853 (a). In .050″ and greater, it meets FAR §25.853 (b).

Over 200 developed colors are available. Five distinctive standard textures further expand design choices. The minimum order quantity for Kydex 100 is as low as one sheet.

Kydex® 657-This formulation offers <100/100 heat release and is as easy to form as Kydex 100. In all gauges, it meets FAR §25.853 (a) and (b). Standard gauges are available from .040″ to .187″. Over 200 developed colors and five standard textures are available. The minimum order quantity is approximately 600 pounds.

Key Characteristics of KYDEX®

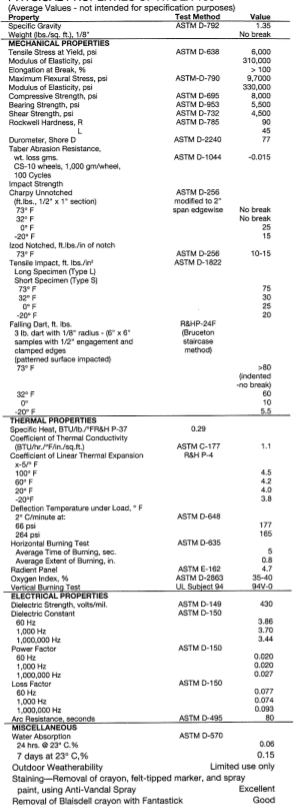

RIGIDITY KYDEX® thermoplastic sheet is among the most rigid of thermoforming materials – up to 50% stronger than many of its competitors. This allows thinner gauge, lighter weight parts with no compromise in strength.

FORMABILITY KYDEX® sheet is unsurpassed in the breadth of its forming range, extensibility and hot-tear strength. It’s also extremely easy to work with once formed

FIRE RETARDANCY KYDEX® sheet is available in several formulations, each of which meet or exceed stringent flame and smoke retardancy requirements.

IMPACT & ABRASION RESISTANCE For tensile strength, hardness, abrasion resistance and impact strength, few thermoplastic materials are tougher than KYDEX® sheet.

CHEMICAL RESISTANCE The KYDEX® family of acrylic/PVC alloy sheet is more resistant to a wider range of concentrated chemicals than most other thermoplastics.