What is a Fluidic Management System?

Fluidic systems and solutions provide the means to transfer fluids entering, flowing throughout, and exiting an application. The types of fluids involved vary extensively by industry and purpose, but often include air, blood, chemicals, reagents, sterilizing cleaners, waste, or water. The design, material selection, and integrated components of a fluidic system are highly dependent upon the type of fluid that they are carrying, as well as the devices that they are connected to. Piedmont CMG has the expertise to help engineers identify the optimal materials, components, and design needed to create a fluidics solution for OEMs developing new applications. Let’s take a look at some of the fluidic system solutions that CMG is capable of providing to product design engineers who are developing the fluidic management systems within their device.

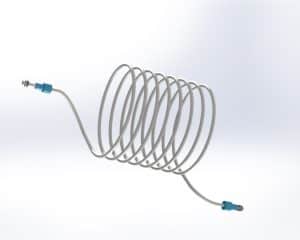

How are Tubing Assemblies used in a Fluidic Management System?

Tubing assemblies are the most commonly used component of successful fluidic systems due to their low cost, ease of use, variety of materials, and simplicity of design. Piedmont CMG supports many OEMs across a wide spectrum of industries with value-added tubing assemblies that can be chemically inert for the reagents or specimen on the sample side of an instrument, or soft tubing assemblies for the wash and waste side of an instrument. We can help you select the tubing material that best fits your needs – whether that’s a tube that can withstand harsh chemicals, high pressure, and extreme temperatures, or provide improved flexibility and low moisture absorption.

Flanged Tubing Assemblies

Connection Fittings for Flanged Tubing Assemblies

After selecting the tubing materials and flanged endings, the next step in designing a fluidic management system is to figure out how all of the components are going to be connected. Here again, Piedmont CMG has the experience and technology to guide customers to success. We provide a wide range of connection fittings in different sizes and materials to allow easy, quick, and secure connections between tubing, manifolds, pumps, valves, sensors, switches, and various other connection points. Just as the tubing

Tubing assemblies are an indispensable part of fluidic management systems, but CMG has much more to offer OEMs who are looking for a total fluidics solution. Be sure to check back soon to learn more about designing a fluidic management system with our other capabilities, including: labeling, tubing kits, fluidic manifolds (machined and diffusion bonded), bottle and cap assemblies (for water, waste, and reagents), as well as flow testing and other fluidic validation services.