What is Vapor Polishing?

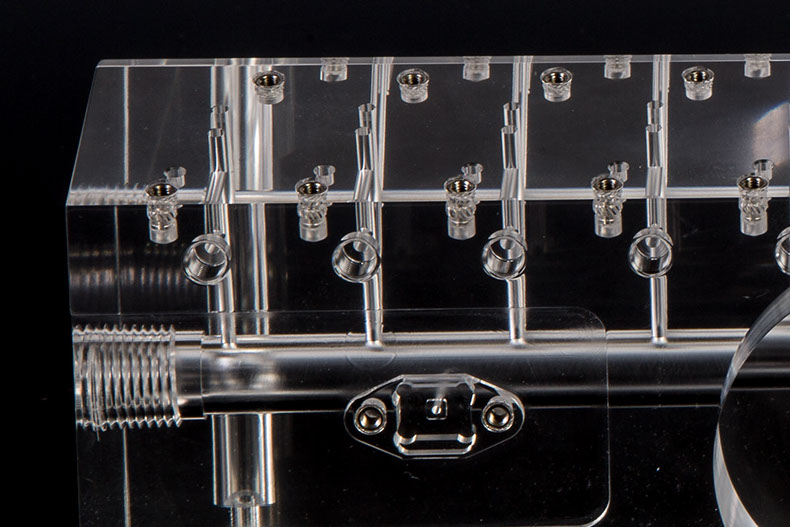

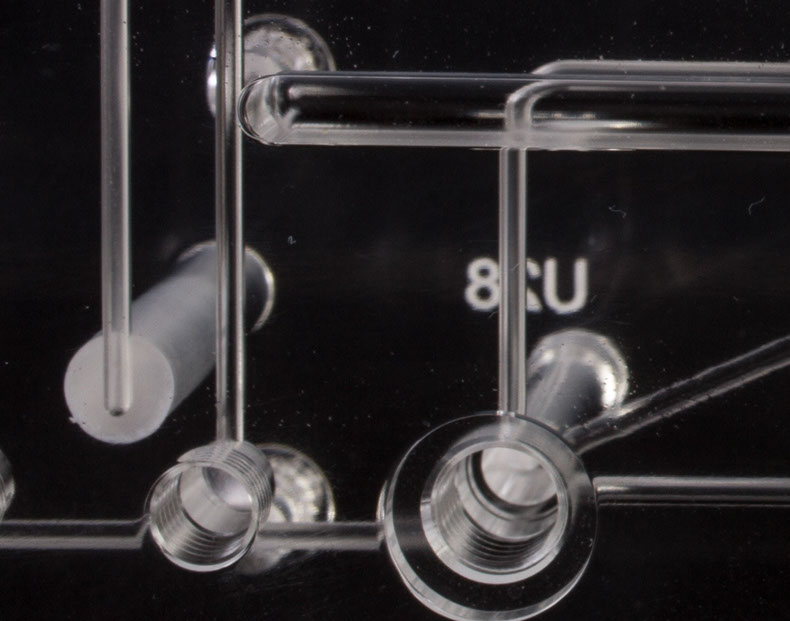

Vapor polishing is a technique that can be utilized in professional plastics processing to enhance the surface finish of amorphous thermoplastics of Acrylic (PMMA), Polysulfone (PSU), Polyetherimide (PEI) also known as Ultem, and Polycarbonate (PC). When done correctly to precision machined surfaces, the transparency of polymer parts can be enhanced.

How does

Vapor Polishing Work?

The basic principle of the process is the application of solvent vapor that reacts to the polymer surface, channels, and bores of a fluidic part. On a microscopic level, the vapor smooths the peaks of the surface of the plastic part and therefore enhances the optical appearance due to the refraction of light. It is also commonly utilized to enhance microfluidic passages for efficient and consistent flow.

Vapor Polishing of Machined Plastic Parts

Vapor polishing at CMG utilizes precise and highly controlled equipment to ensure effective and consistent application to the designated surfaces. This is important because the process requires parts with no residual stress, burns, or tool marks. This method of polishing will only magnify the visual imperfections with inexperienced plastic machining and could also lead to cracking or crazing of the part.

Do I Need

Vapor Polishing?

Vapor polishing may or may not be the most effective way to achieve the optical and flow specifications that your application requires. Contact the professionals at Piedmont CMG for results driven recommendations. Piedmont CMG’s unique processing in many types of part geometries creates optical quality finishes without secondary processes. This reduces costs and maximizes the performance of the base polymer.