Diffusion Bonding PEI (Ultem™)

Diffusion Bonding Ultem™ is rapidly becoming one of the top services requested at Piedmont CMG. In this process, multiple layers of PEI material are bonded together at the molecular level to produce a uniform part without the use of glues, solvents, or other adhesives. The resulting product is free of contaminants and, therefore, highly desirable for applications in industries such as: In Vitro Diagnostics (IVD), DNA Sequencing, Surgical Equipment, Food & Beverage, and many more.

Why Choose Ultem™ (PEI) for Diffusion Bonding?

Ultem™ is highly desired for diffusion bonding applications for a quite a few reasons, but namely because it has the properties of a high performance plastic without the premium cost. Also, it is relatively easy to bond in comparison to many other polymers. Ultem™ is a great choice for high service temperatures, both in air and water, and can withstand repeated autoclaving. It has excellent tensile strength, broad chemical resistance, flame resistance, and even resistance to UV and gamma radiation. On top of all that, Ultem™ has very good finishing characteristics, so your finished manifold can look like the showpiece that your instrument deserves.

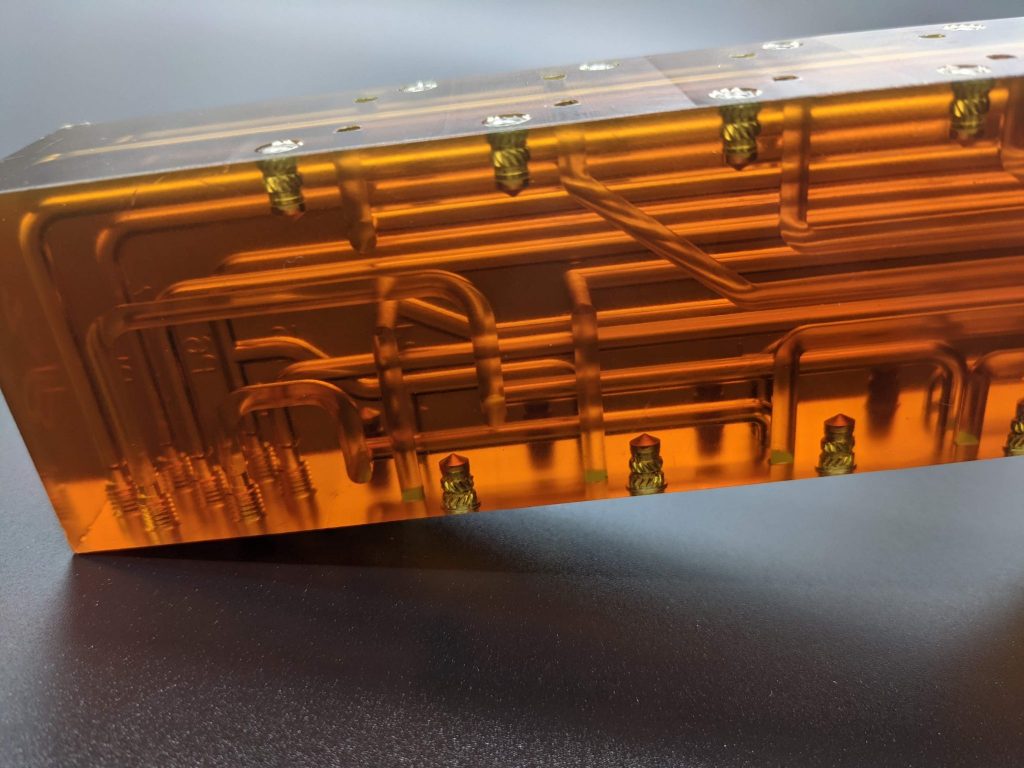

Diffusion Bonding Ultem™ (PEI) Manifolds

Diffusion bonded Ultem™ manifolds are utilized for fluidic and microfluidic systems to provide an elegant solution to a whole host of application design and service requirements. Bonded Ultem™ manifolds can include multiple layers with countless channels to connect all fluid paths in an instrument through one critical, central hub. Contact us anytime to speak to an expert and find out how to include a diffusion bonded Ultem™ manifold in your new fluidic system!